FLIERMOUSE Near-Infrared (NIR) Transmissive PMMA: Material Properties and Applications

1. Fundamental Properties(Thickness:1.5mm)

• Chemical Basis

FLIERMOUSE engineers enhance conventional PMMA (92% light transmittance, density 1.19g/cm³) through molecular structure modification or additive optimization, achieving 93% transmittance in the 700-1650nm NIR band while maintaining high hardness (pencil hardness: 2H-6H) and thermal stability (HDT: 120°C. This innovative material is ideal for applications such as infrared sensing, facial recognition, optical inspection, and more.

• Key Modifications

Selective Light Transmission: Special formulations or polymer branch adjustments enable visible light blocking(black appearance) with high NIR transparency.

Customizable Wavelengths: Supports tailored transmittance for sub-bands (e.g., 850-1650nm, 905-1650nm) to match various infrared LED wavelengths.

2. Performance Advantages

• Optical Performance

NIR Transmittance: 93% (780-1650nm), outperforming standard PMMA (limited to IR <2800nm).

UV Blocking: Blocks UV below 300nm; optional coating enhances shielding for 300-400nm UV.

• Mechanical & Thermal Properties

High Hardness: Scratch-resistant with 2H-6H pencil hardness.

Enhanced Heat Resistance: HDT of 120°C vs. standard PMMA (95-105°C).

Lightweight: Density is 43% of glass, ideal for weight-sensitive applications.

• Environmental Stability

Resistant to acids, alkalis, and organic solvents (avoid ketones/ethers).

Flammable (ignition point: 458°C), requiring flame-retardant treatment.

3. Core Applications

• Smart Sensing & Optical Systems

ADAS/Autonomous Vehicles: LiDAR covers, IR camera lenses (compatible with 905nm/1550nm lasers, 850nm IR).

Biometrics: IR windows for finger vein/iris recognition.

Security: Night-vision camera filters (NIR-transmissive, visible light-blocking).

• Industrial & Consumer Electronics

IR Touchscreens: Enable touch functionality while hiding sensors.

Remote Controls: Black housings transmitting IR signals (e.g., TV remotes).

• Specialized Scenarios

Hunting Cameras: Covert nighttime imaging.

Medical Devices: Optical components for NIR detection instruments.

4. FLIERMOUSE NIR PMMA vs. Conventional PMMA

| Property | Conventional PMMA | FLIERMOUSE NIR PMMA |

|————————|—————————-|——————————–|

| Transmittance Band | Visible light (92%), partial UV/IR | NIR (94%, customizable 700-1650nm) |

| Appearance | Transparent | Black (blocks visible light) |

| HDT | 95-105°C | 120°C |

| Primary Use Cases | Displays, lighting, décor | IR sensing, optical recognition, autonomous systems |

5. Key Considerations

Optical Design: Match NIR PMMA type to IR LED wavelength (e.g., 905nm LEDs → 850-1650nm variant).

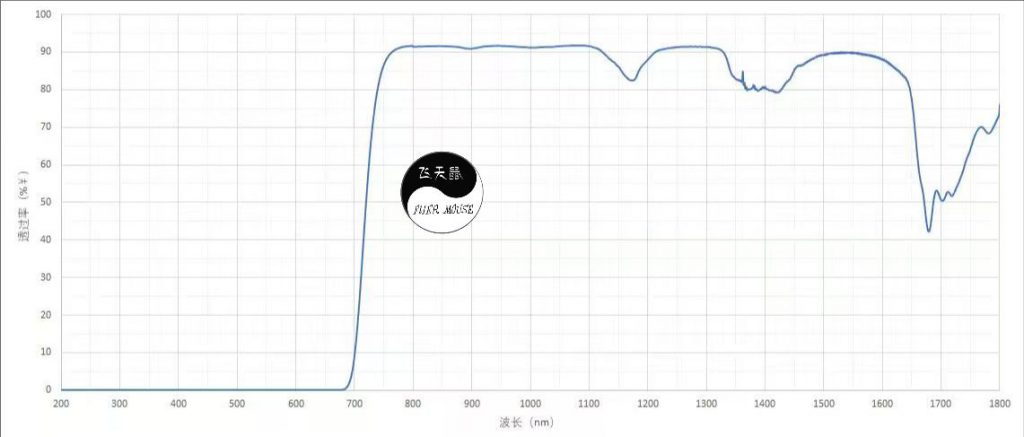

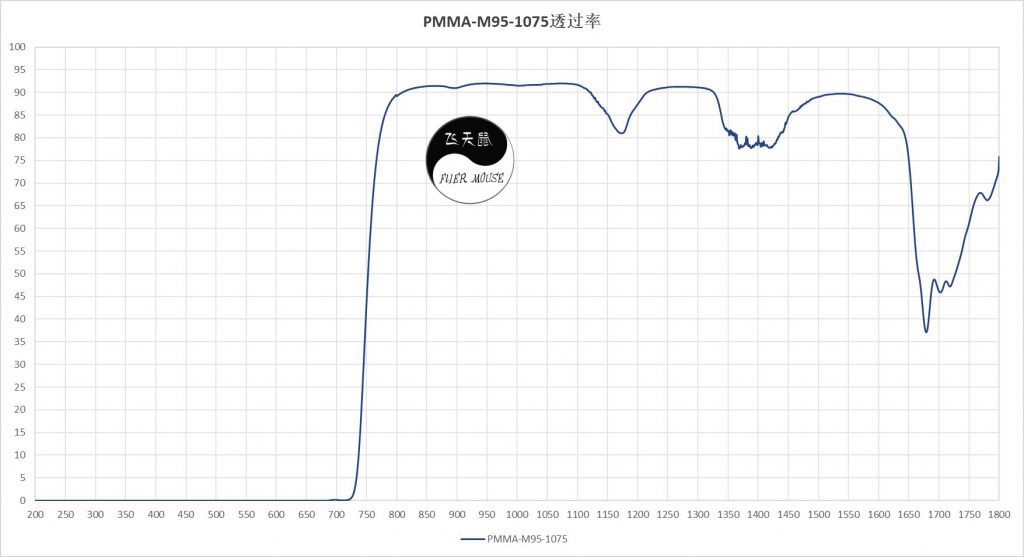

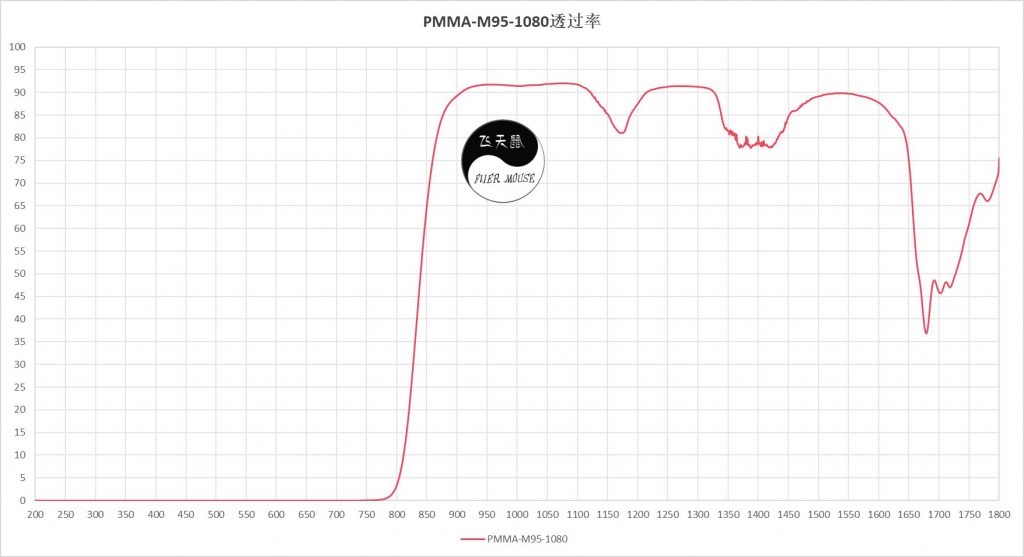

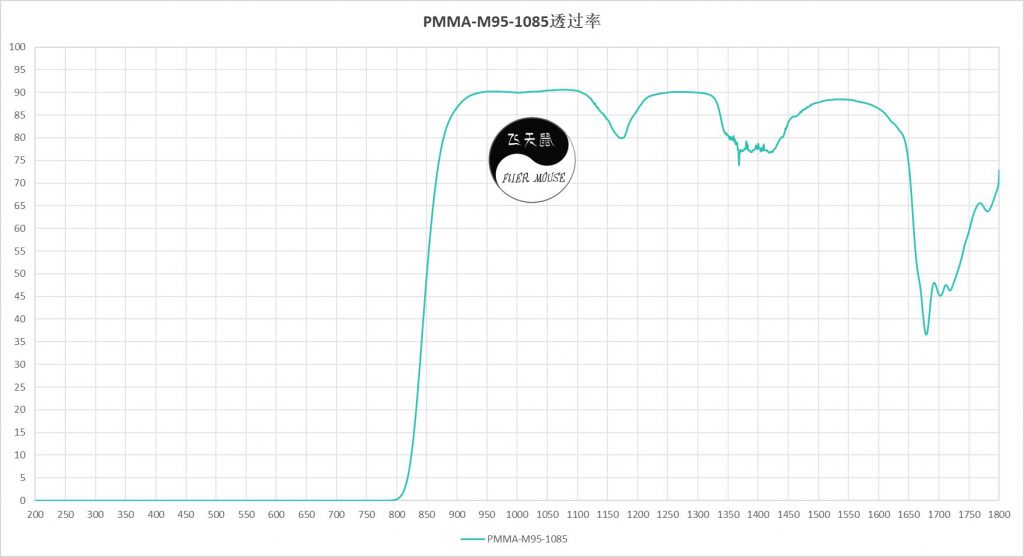

| NIR Wavelength Range (nm) | Highlights |

|---|---|

| 700–1650 (NIR PMM- M95-1073J) | Broad-spectrum transmission,for 800nm or 850nm LED |

| 780–1650 (NIR PMMA-M95-1080) | High transparency up to 93%,for 850nm LED |

| 850–1650 (NIR PMMA-M95-1085) | Compatible with various IR LEDs,for 905nm or 940nm LED |

| 905–1650 (NIR PMMA-M95-1090) | Optimized for safety and remote control,for 940nm LED |

| 1100–1650 (NIR PMMA-M95-1550) | Ideal for NIR imaging and sensing,for 1550nm LED |

Conclusion

FLIERMOUSE’s NIR PMMA M95, with precise wavelength control and optimized performance, is an ideal material for advanced infrared optical systems. Its black appearance ensures stealth, while 94% NIR transmittance supports cutting-edge applications in autonomous driving, biometrics, and covert surveillance. Customizable properties further unlock potential in next-gen technologies, positioning it as a cornerstone of the NIR-enabled engineering era.

发表回复