Core Property Comparison

| Property | Near Infrared-Transmitting PMMA | Near Infrared-Transmitting PC |

|---|---|---|

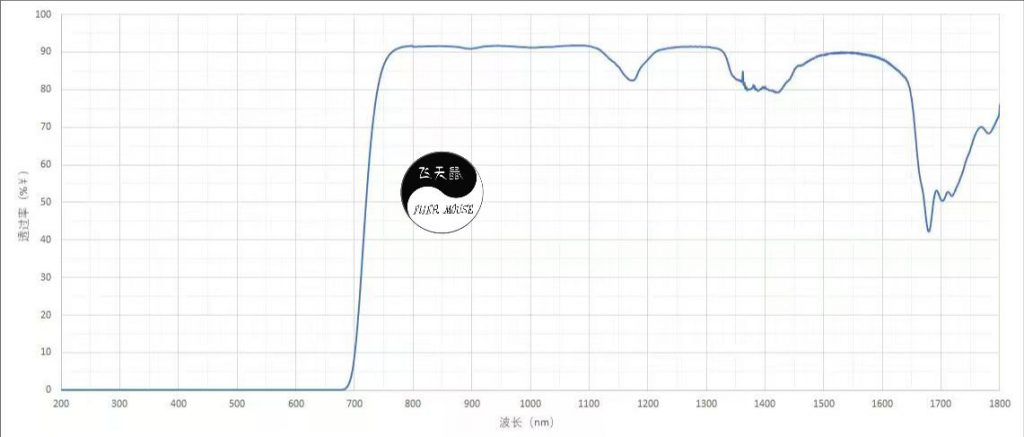

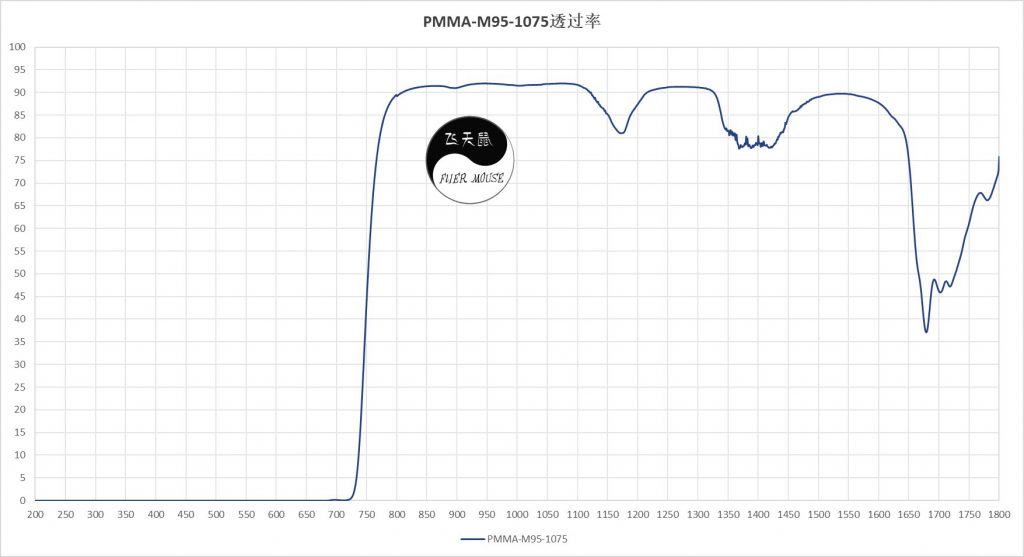

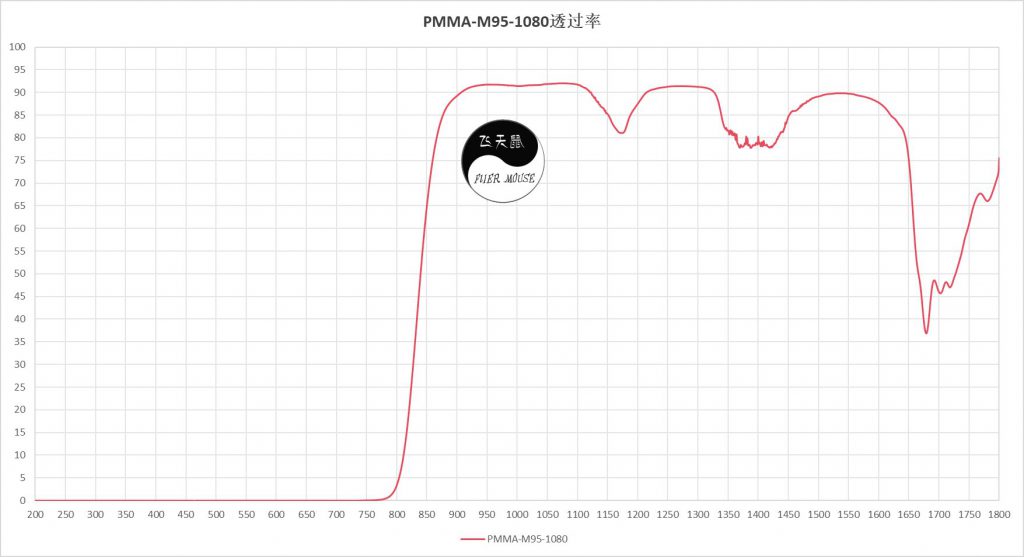

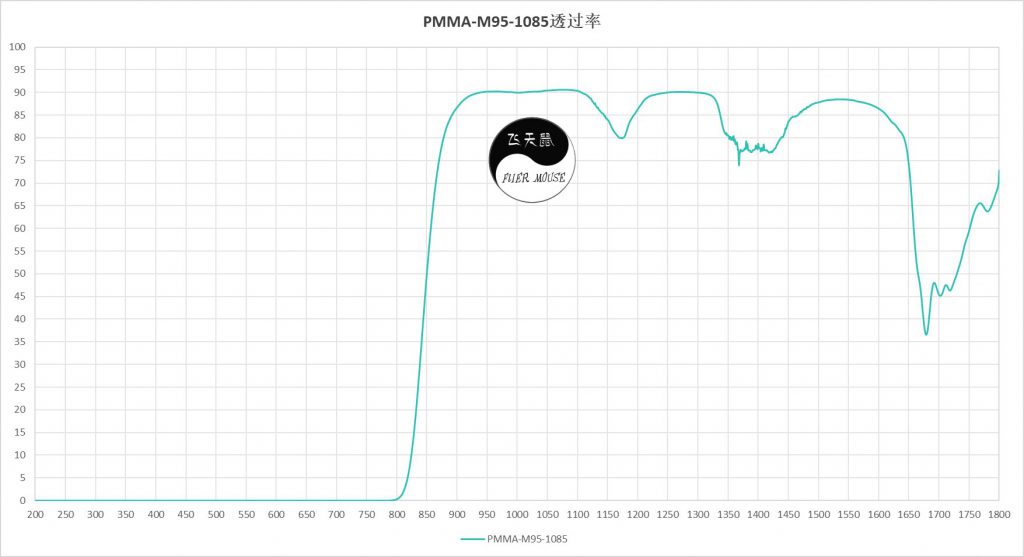

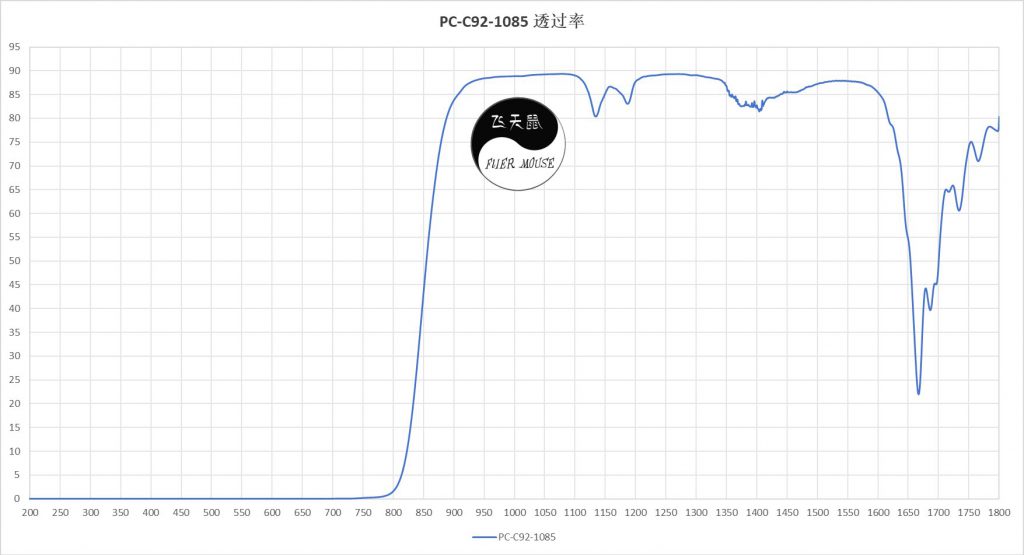

| Optical Performance | – NIR transmittance (780–1650 nm) up to 94% – Blocks UV (200–400 nm) and visible light (400–780 nm) | – Slightly lower NIR transmittance (typically 90–93%) – Blocks UV/visible light |

| Physical Properties | – Density: 1.2 – Refractive index: 1.496 (matches standard PMMA) | – Density: 1.2 – Refractive index: 1.586 (matches standard PC) |

| Mechanical Properties | – Pencil hardness: 1H–6H (requires surface hardening) – Excellent scratch resistance – Moderate HDT (90–121°C) | – Inherent high impact resistance – Lower hardness (upgradable to 3H–5H via coating) – Higher HDT (130–140°C) |

| Processability | – Mature injection/extrusion processes, good melt flow | – Higher processing temperatures, requires pre-drying (moisture-sensitive) |

| Appearance | High-gloss black, strong concealment | Similar black appearance, slightly broader light transmission band |

Technical Differences

- Optical Design Compatibility

- PMMA: Lower refractive index (1.496) suits thin lenses/windows (e.g., consumer electronics cameras).

- PC: Higher refractive index (1.586) reduces optical component thickness but may introduce chromatic dispersion, requiring anti-reflective coatings.

- Heat Resistance & Environmental Adaptability

- PC: Higher HDT (130–140°C) fits high-temperature environments (e.g., automotive LiDAR housings).

- PMMA: Requires heat-resistant additives or cross-linking to improve HDT; prone to slight deformation under prolonged heat.

- Impact Resistance & Durability

- PC: Superior inherent impact resistance (notched impact strength >600 J/m), ideal for military/outdoor applications.

- PMMA: More brittle; relies on surface hardening coatings for scratch resistance.

Application Selection Guide

| Scenario | Recommended Material | Rationale |

|---|---|---|

| Autonomous Vehicle LiDAR Lenses | PMMA | High transmittance + surface hardness for precision optics |

| High-Temperature Industrial Sensor Windows | PC | Heat resistance + impact strength for harsh environments |

| Medical Endoscope Sheaths | PMMA | Biocompatibility + ease of thin-wall processing |

| Military Night Vision Housings | PC | Impact resistance + concealment for tactical use |

| Consumer Electronics IR Camera Covers | PMMA | High-gloss finish + cost-efficiency for mass production |

Challenges & Solutions

- PMMA Limitations

- Issue: Limited heat resistance; potential yellowing in outdoor use.

- Solution: Add UV stabilizers (e.g., HALS) and heat-resistant fillers (e.g., SiO₂).

- PC Processing Difficulties

- Issue: High hygroscopicity; requires strict pre-drying (humidity <0.02%).

- Solution: Use vacuum dryers + in-mold dehumidification processes.

- Recyclability

- PMMA: Physically recyclable, but hardening coatings require separation.

- PC: Chemical recycling (hydrolysis) is complex; needs specialized additive tagging.

Future Trends

- Hybrid Materials: Develop PMMA/PC blends to balance transmittance, heat resistance, and impact strength.

- Smart Coatings: Self-healing coatings to enhance durability for outdoor applications.

- Eco-Friendly Design: Bio-based additives to improve recyclability and sustainability.

Conclusion

Near Infrared-transmitting PMMA and PC each excel in specific areas:

- PMMA: Preferred for optical precision, surface hardness, and cost-sensitive applications (e.g., consumer electronics).NIR-transmissive thermoplastic(PMMA )with high transmittance(94%) at 850nm/940nm.

- PC: Ideal for high-temperature, impact-resistant environments (e.g., automotive, military).NIR-transmissive thermoplastic(PC )with high transmittance(92%) at 850nm/940nm.

Material selection should balance NIR transmission, mechanical performance, environmental tolerance, and cost. Future advancements in composite materials and processing will further expand their applications. - FLIERMOUSE NIR-transmissive thermoplastic SERIES(thickness:1.5mm):

Home

Services

Services

发表回复