[Ⅰ] Definition of Infrared-Transparent Polymer Materials

Infrared-transparent polymer materials – Raw material pellets – 25Kg/ bag

NIR-transparent polymer material pellets and profiles

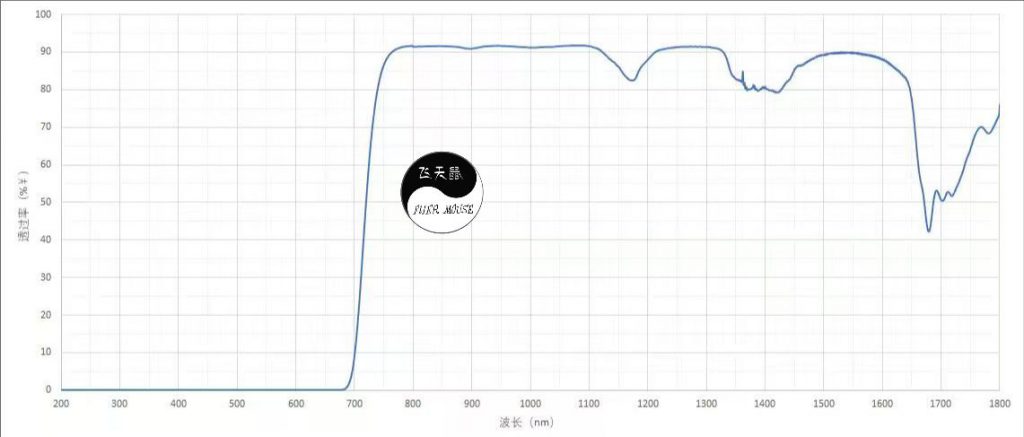

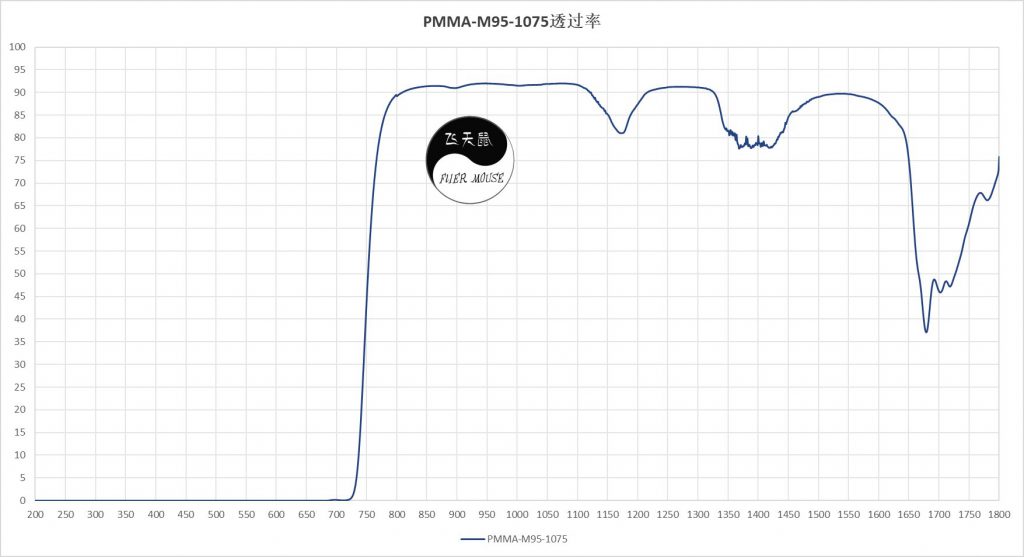

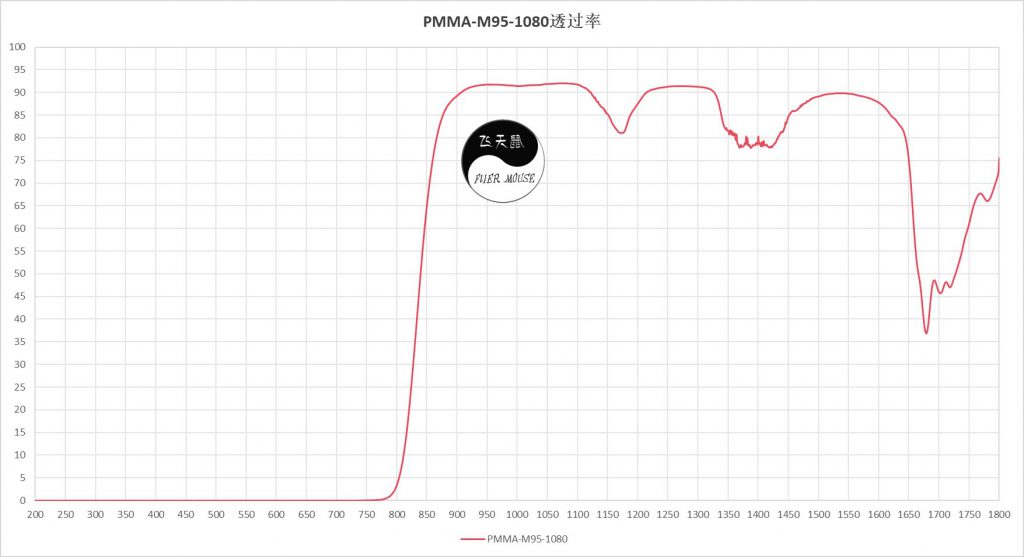

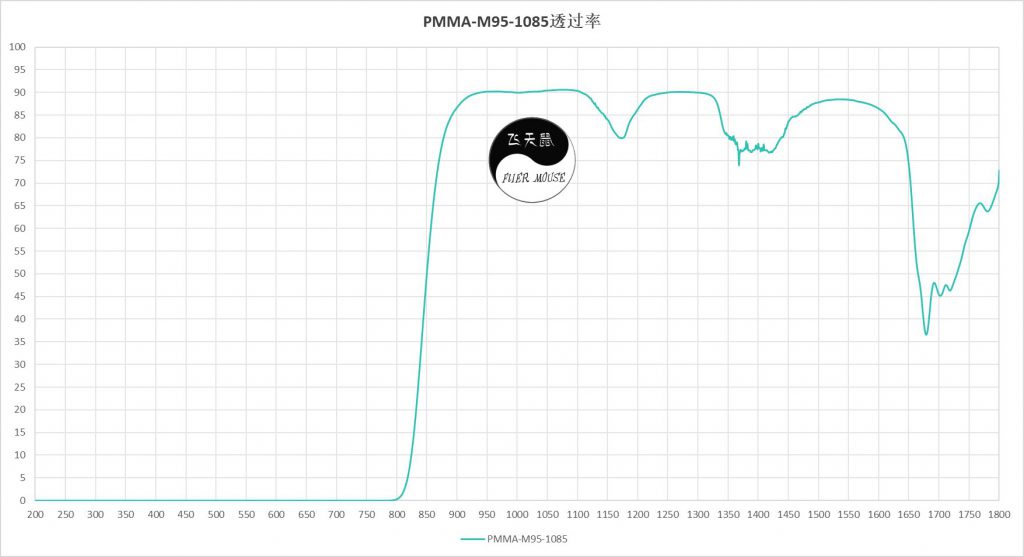

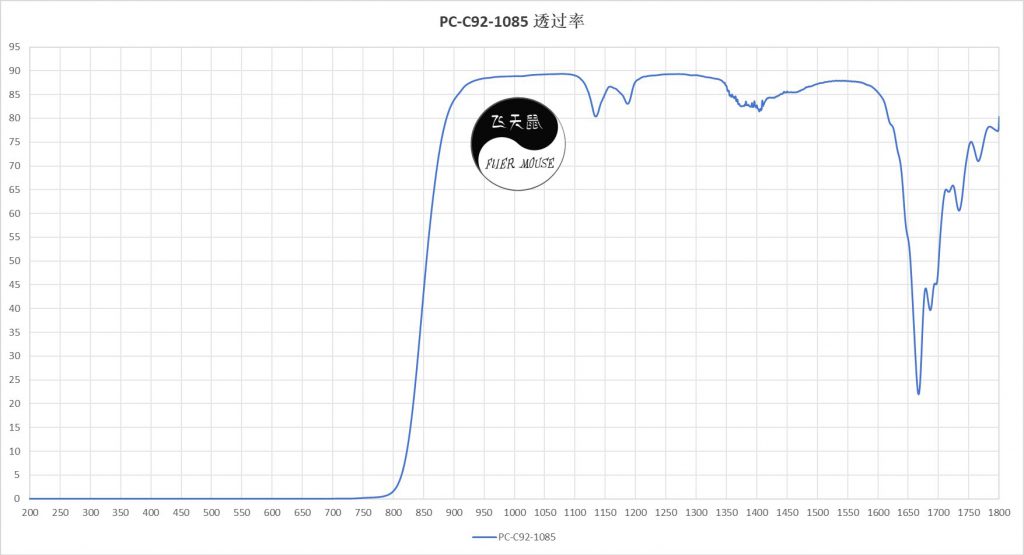

Transmittance spectrum of FLIERMOUSE NIR series (thickness:1.5mm)

【I】Core Definitions and Classification of Near Infrared Transparent Plastic Materials Definition

Functional Characteristics : Transmittance >90% in specific infrared bands (NIR/MIR/FIR) while blocking visible/UV light (e.g., NIR materials block 99% UV). Predominantly black in appearance.Classification Criteria :Band Wavelength RangeTypical Materials Applications Near-Infrared 780~1650 nm PC, PMMA, ABS, PET Consumer electronics, Automotive, Security Mid-Infrared 2000~5000 nm COP Medical devices (experimental) Far-Infrared 7000~14000 nm PTFE Military, Aerospace Ultra-Long Wave 1 mm~100 m Electromagnetic wave materialsCommunications, Radar

Material Typical Grade Advantages Disadvantages Key Applications NIR PC C92 Series High impact resistance (drop-proof), HDT 137°C Low surface hardness, scratch-prone, transmittance <94% LiDAR windows, security camera filters NIR PMMA M95 Series Highest transmittance (94%), weather resistance Brittle, low thermal stability (HDT ≈121°C) Optical lenses, medical endoscopes NIR ABS A90 Series Low density (1.04–1.06 g/cm³), easy processing Inferior thermal/chemical resistance vs. PC/PMMA Large appliance housings, robot navigation modules NIR PET – Chemical resistance, low cost Crystallinity-induced uneven transmittance Sensor windows, optical packaging

【III】Developments in Mid- and Far-Infrared Materials Mid-Infrared (2000–5000 nm)

COP (Cyclo Olefin Polymer) : Low birefringence, cryogenic resistance (-100°C), used in missile IR windows and astronaut visors.

Far-Infrared (7000–14000 nm)

PTFE (Polytetrafluoroethylene) : Stable broadband transmittance, challenging processing (sintering required).

【IV】Key R&D and Testing Technologies Core Technical Pathways

Molecular Structure Modulation :

Side-chain modification : Adjust ester group ratios in PC to reduce C-H bond IR absorption peaks.Additive formulation : Nano-ZnSe (enhances MIR transmittance) or SiO₂ (improves abrasion resistance).

Band Customization :

Case study : Suppress 1400–1500 nm water absorption peaks to align with 1550 nm LiDAR wavelengths.

Performance Balancing :

Incorporate benzotriazole UV absorbers while maintaining >90% IR transmittance.

Testing Equipment List Test Item Equipment Key Parameters IR Transmittance FTIR Spectrometer Wavelength resolution ≤4 cm⁻¹ Mechanical Properties Universal Tensile Tester, Izod Impact Tester Tensile speed: 5 mm/min Thermal Stability Heat Deflection Temperature (HDT) Tester Load: 1.82 MPa Flammability UL-94 Combustion Tester Vertical burn rating (V0/V1/V2)

【V】Core Application Scenarios and Case Studies Autonomous Driving & Automotive Industry

ADAS LiDAR Window :

Material : NIR PMMA M95-1073J (94% transmittance, 105°C heat resistance).Validation : Passes 85°C/85% RH dual-85 test, SAE J400 gravel impact resistance.

Security & Surveillance

Covert IR Illumination Filter :

Material : Black NIR PC C92-1073 (>99% visible light blocking, 93% transmittance @850 nm).

Medical Sterilization Devices

Endoscope Sleeve :

Material : COC (γ-ray sterilization resistance, >90% transmittance @3–5 μm).

【VI】Injection Molding Full-Process Specifications Mold Design Requirements Parameter Specification Impact Optical precision (Rt) <0.5 μm Light path deviation Surface roughness (Ra) <0.01 μm Reduces diffuse reflection (>5%) Mold lifespan >380,000 cycles Prevents optical surface wear

Injection Machine & Screw Selection Material Screw Type L/D Ratio Compression Ratio Machine Type NIR PC C92 Gradual compression (40–50% zone) 15–20 2–3 Electric precision press NIR PMMA M95 Gradual compression (≥50% zone) 15–20 2–3 Electric precision press NIR ABS A90 Gradual compression (20–30% zone) 15–20 2–3 Electric precision press

Process Parameters Material Drying Conditions Mold Temperature Melt Temperature Critical Notes NIR PC C92 120°C, 3–6h 80–120°C (heated) 260–300°C Avoid multi-stage injection (prevents molecular orientation imbalance) NIR PMMA M95 80–95°C, 3–4h 50–65°C 200–240°C Packing pressure ≤80% (prevents stress cracking) NIR ABS A90 90°C, 2–4h Ambient cooling 180–220°C Mold temp >40°C causes shrinkage fluctuation

【VII】Future Trends and Challenges

Metamaterial Structures : Biomimetic moth-eye nanostructures (period <1 μm) for broadband transmittance enhancement (+5–8%).Hybrid Materials : PC/PMMA blends (with compatibilizers) balancing hardness and transmittance.Eco-Friendly Upgrades : Halogen-free flame-retardant NIR ABS (UL94 V0 certification).

Engineer Recommendations

Home

Services

Services

发表回复