★ Basic Characteristics:

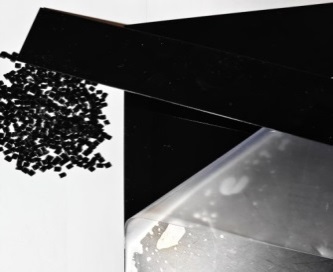

Black NIR-transmitting PMMA pellets and sheets

Near Infrared-transmitting acrylic (near infrared transmitting polymethyl methacrylate or near infrared transmitting PMMA)granular material is suitable for injection molding or extrusion, with a density of 1.19 and a refractive index of 1.496.

FLIERMOSUE engineers achieve high transmittance(94%) in the near-infrared (NIR) spectrum (700~1650 nm) while effectively blocking visible light (400~780 nm) and ultraviolet (UV) rays (200~400 nm) through molecular structure modification or additive regulation. This specially engineered PMMA plastic (acrylic material) is referred to as infrared-transmitting acrylic. It exhibits a high-gloss black appearance, high hardness (2H, upgradable to 6H with hardening treatment), excellent scratch resistance, and a high heat deflection temperature (HDT:121°C).

★ Near Infrared-Transmitting Acrylic Raw Material Granules & Sheets

Black NIR-transmitting PMMA Sheet 2400*1200*0.5~8.0 mm

R&D & Manufacturing:

- Selective Light Transmission & Blocking:

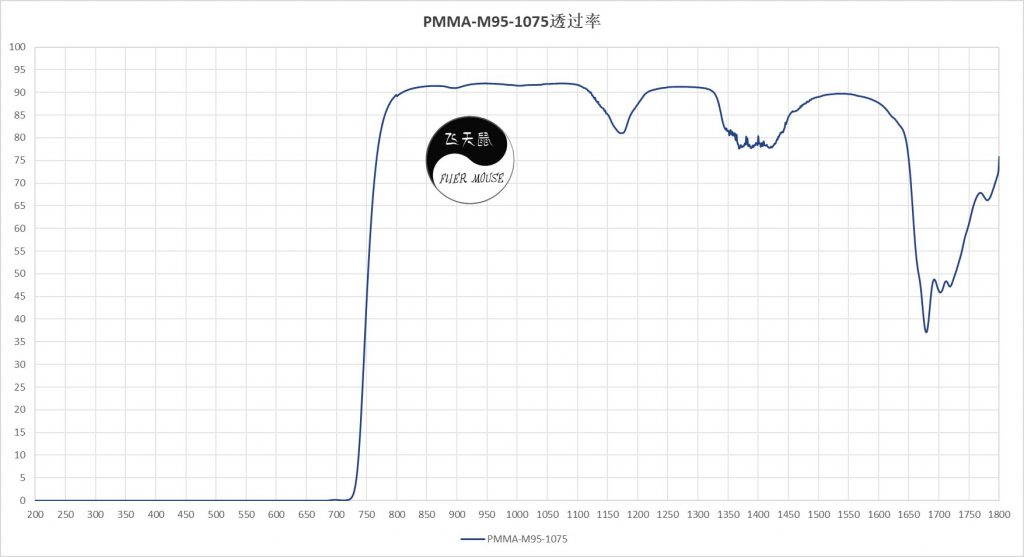

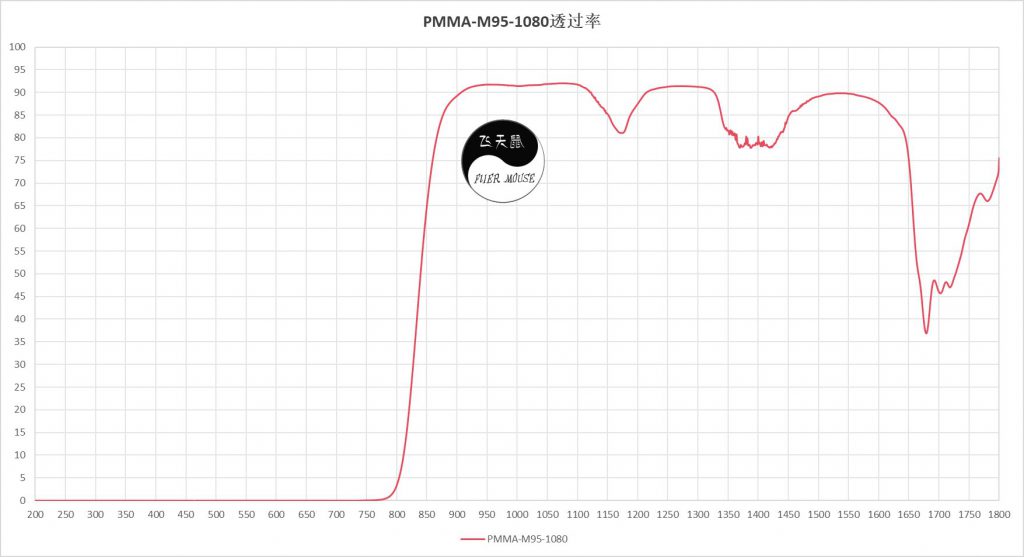

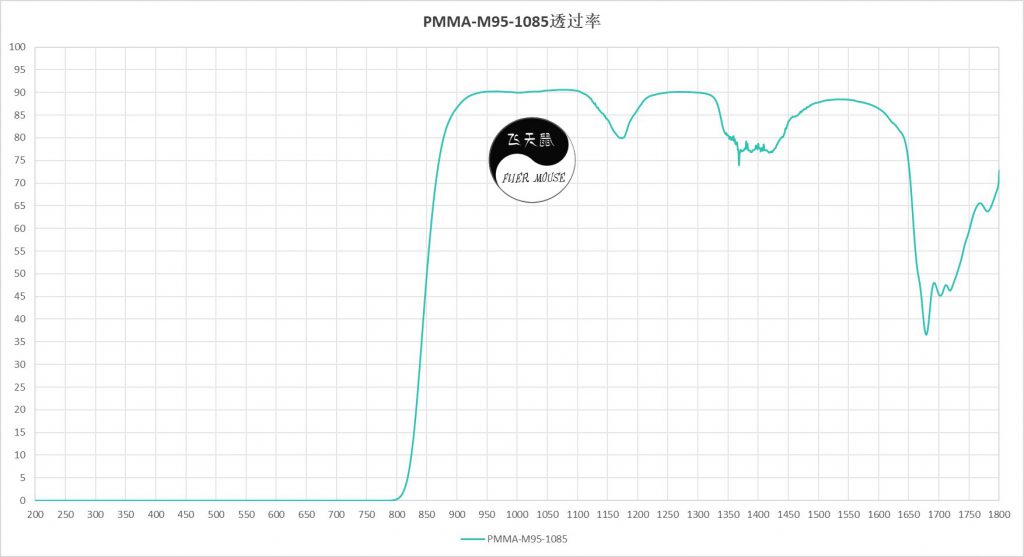

FLIERMOSUE engineers employ specialized formulations or polymer side-chain adjustments to precisely block visible light and unwanted IR wavelengths while allowing only specified IR wavelengths to pass through. - Customizable Wavelength Ranges:

Custom IR-transmitting acrylic can be tailored to any sub-band within the 700~1650 nm range (e.g., 850~1500 nm, 905~1650 nm) to match different IR LED operating wavelengths for sensors or cameras. - Thickness:1.5mm

★ Performance of Infrared-Transmitting Acrylic:

- Optical Properties:

- High transmittance (up to 94%) in the NIR spectrum (700–1650 nm).

- Effective UV blocking, making it suitable for outdoor applications.

- Mechanical & Thermal Properties:

- High hardness (2H, upgradable to 6H) with scratch resistance.

- Modified versions feature a higher HDT (100~121°C) , making them ideal for automotive applications (e.g., ADAS lenses).

- Lightweight:

- Density is only 43% that of glass, beneficial for weight reduction.

- Environmental Stability:

- Resistant to acids, alkalis, and organic solvents (avoid ketones/ethers).

- Flammability (ignition point: 458°C) requires flame-retardant considerations.

★ Core Application Fields:

- Smart Sensing & Optical Systems:

- ADAS/autonomous driving, LiDAR covers, IR camera lenses (compatible with 905 nm/1550 nm lasers & 850 nm IR).

- Biometric Recognition:

- IR-transmitting windows for finger vein & iris recognition devices.

- Security & Surveillance:

- Night-vision camera filters (transmit IR while blocking visible light).

- Industrial & Consumer Electronics:

- IR touchscreens (allow IR penetration for touch sensing while hiding sensors).

- Remote Control Devices:

- Black enclosures for IR remote signals (e.g., TV remotes).

- Specialized Applications:

- Hunting cameras (IR imaging for covert nighttime photography).

- Medical Devices:

- Optical components for NIR detection instruments.

★ Conclusion

FLIERMOSUE engineers optimize IR-transmitting acrylic through precise wavelength control and performance enhancements, making it an ideal material for IR optical systems in automotive and electronics industries. NIR-transmissive thermoplastic(PMMA M95-1073J) with high transmittance (94% )at 850nm/940nm;Users can select the appropriate grade based on their IR LED wavelength:

- 800 nm or 850 nm IR LEDs → 700~1500 nm range (FLIERMOSUE NIR PMMA M95-1073J)

- 905nm, 940nm IR LEDs → 800~1500 nm range (FLIERMOSUE NIR PMMA M95-1080)

Home

Services

Services

发表回复